Don Emery

I am a Senior engineer specialist that works for a world-class bottling company. I love to create and learn new things. Sometimes with my job, I must think outside of the box and create ideas for issues that need to be solved. On top of this, I have taught myself to learn C# and created a few programs and also how to use SQL. Now I wanted to create a website for my profile, and you guessed it I am learning a little about Html and bootstrap.

Experience

Senior Engineering Specialist

∙ Responsible for the identification and resolution of issues, review and revision of processes and procedures,

and enhancement of team member skills.

∙ Support plant operations in achieving the key results in safety, quality, productivity, and cost.

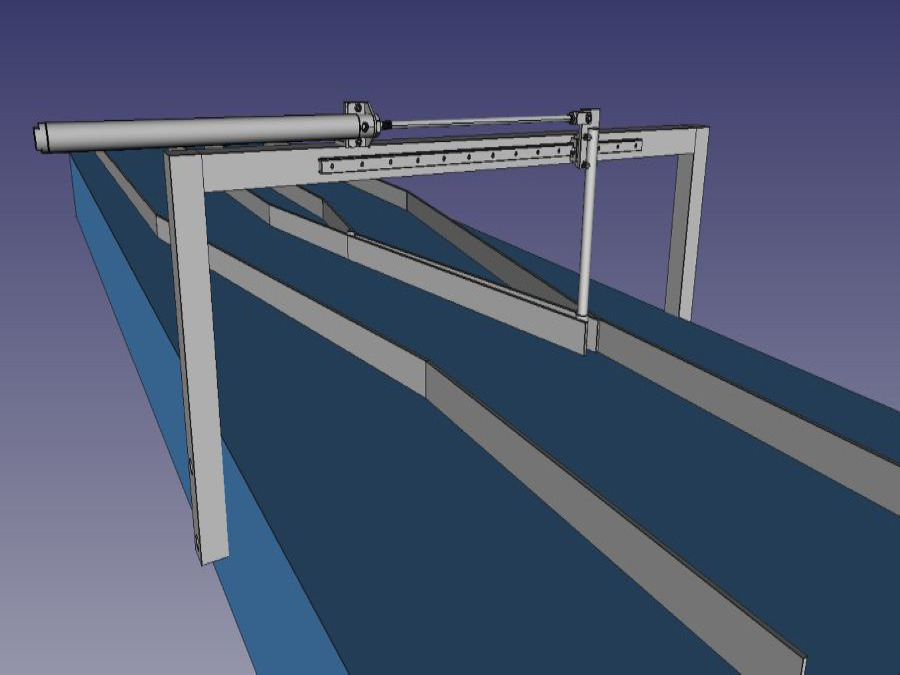

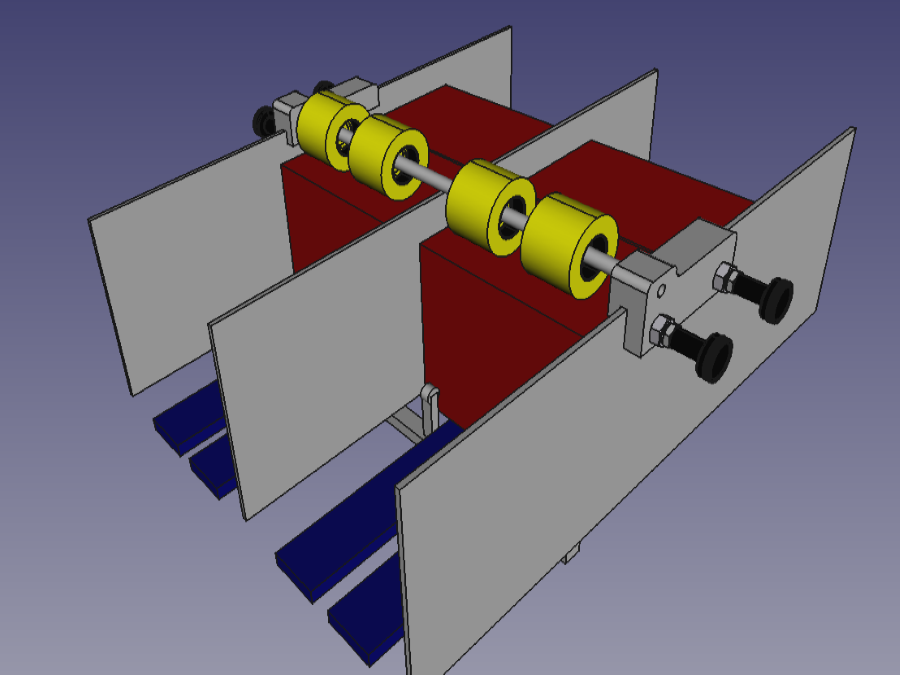

∙ Implementation of new equipment, continuous improvement, and cost savings projects.

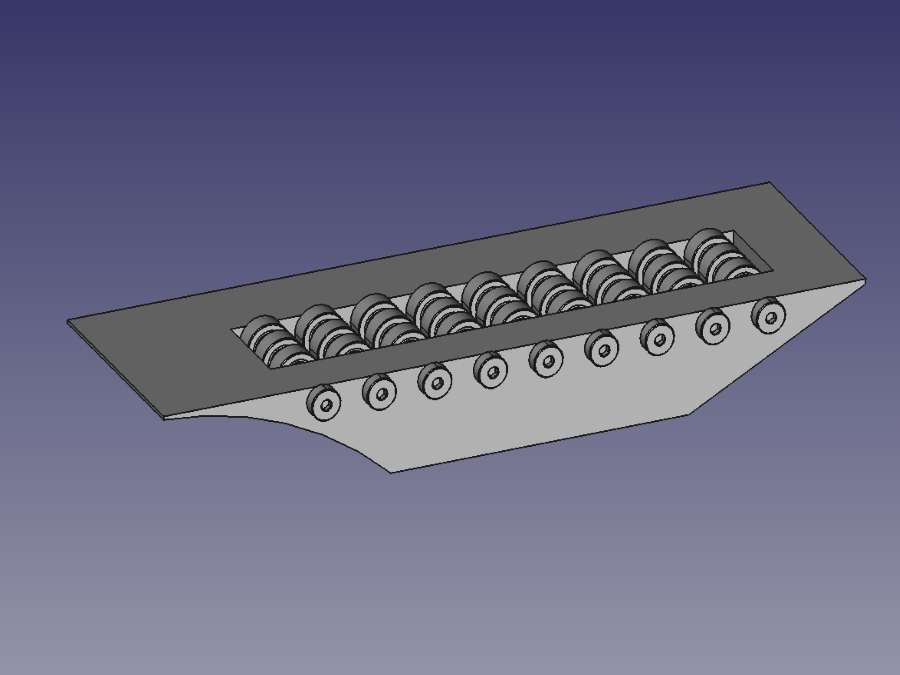

∙ Design and install projects/modifications to production equipment to improve production throughput.

∙ Generated ideas for improving the lines and implementing those ideas while tracking data to ensure efficacy.

∙ Allen Bradley PLC programming and troubleshooting experience.

∙ Manage the backup database for all PLC, HMI, and VFD programs using Asset Centre.

∙ Created and updated PLC programs for existing and integration of new equipment.

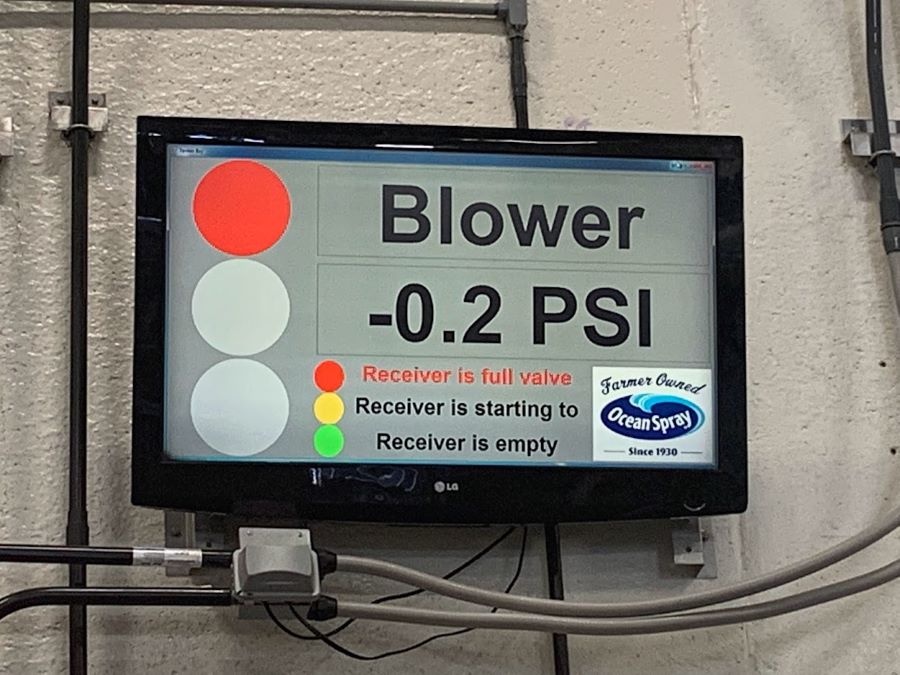

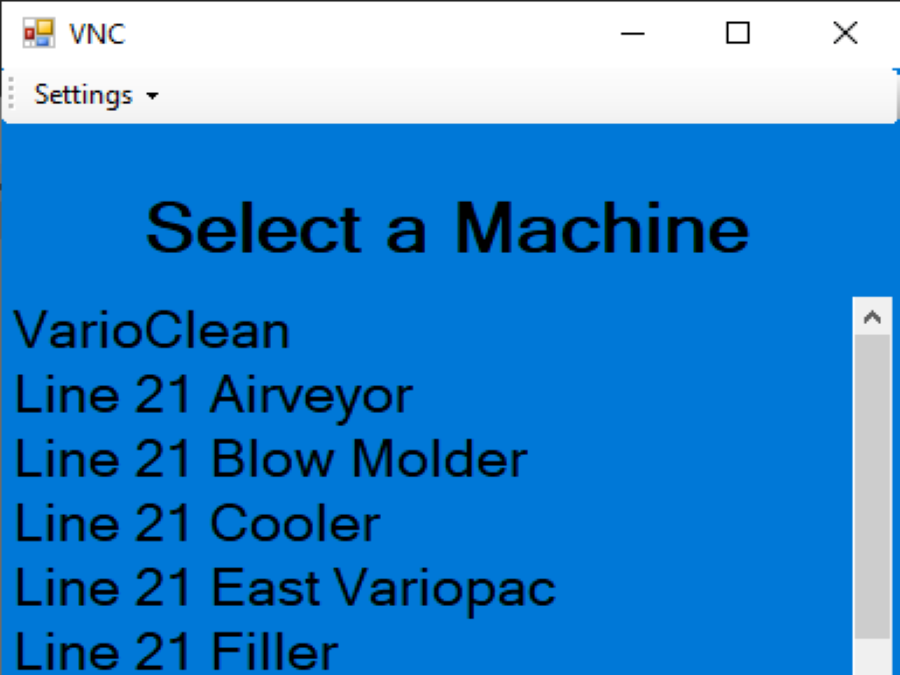

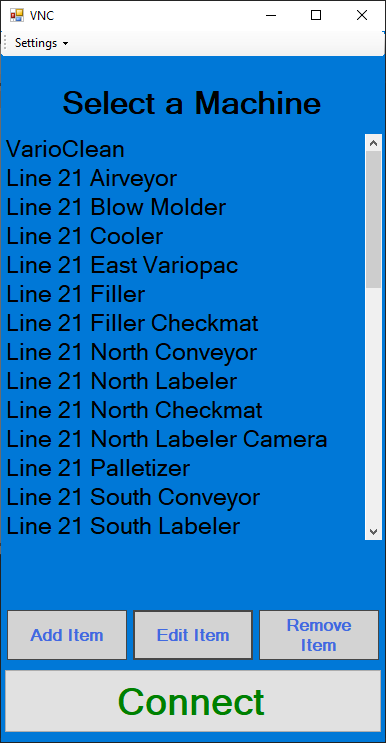

∙ Creating and modifying screens for HMI and Krones Zenon on existing equipment.

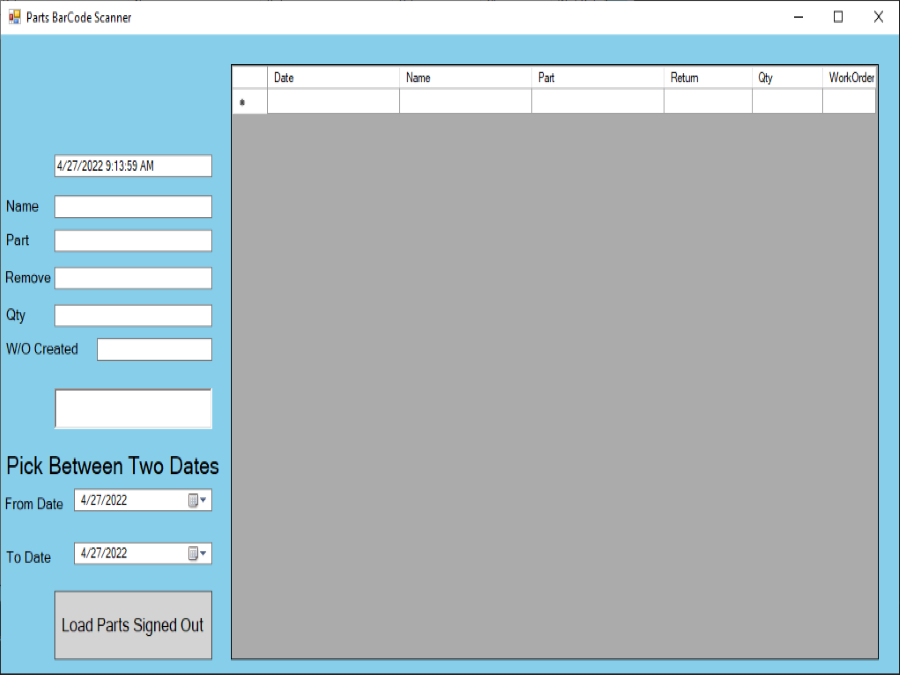

∙ Designing programs and HMI screens using Microsoft Visual Studio.

∙ PC software development using Microsoft Visual C# .NET and SQL Server.

Maintenance Mechanic Lead/SME

∙ Technical experience with several types of high-speed automated machines, such as: Krones, Tetra Pak,

Muerer, and Kaufman.

∙ As a subject matter expert, leads the maintenance team to systematically identify, analyze, and solve issues

to reach optimum solutions in a timely manner. Processes are coordinated as necessary.

∙ Troubleshoot and repair electrical, pneumatic and hydraulic equipment used in manufacturing and facility

equipment.

∙ Knowledge in rebuilding all types of valves and pumps.

∙ Solid problem solving and decision-making skills with the ability to coach others.

∙ Proficient with Maximo, SAP, downtime and Microsoft office.

∙ Successfully completed leadership in development training.

∙ Responsible for team development through identifying technical gaps and initiating training opportunities for

employees. Gap analysis obtained through job audits, statistical data, and employee annual reviews.

Machinist

∙ Using computer-controlled equipment, fabricate close tolerance satellite parts from engineering blueprints.

∙ Calculate and set controls to regulate machining factors, such as speed, feed, coolant flow, and depth and

angle of cut.

∙ Set up and operate a variety of machine tools, such as lathes, milling machines, and grinders.

∙ Fit and assemble parts into complete assemblies, using jigs, fixtures, surface plate, surface table, hand tools,

and power tools.

∙ Enter commands to retrieve, input, and edit computerized machine control media.

∙ Troubleshoot systems accurately and repair breakdowns quickly to maintain operating efficiency.

∙ Verify position of workpiece on machine with gauge blocks, height gauges, dial indicators, and other close

tolerance measuring instruments.

∙ Design fixtures, tooling, and experimental parts to meet special engineering needs.

∙ Responsible for training and setting up machines for other employees.

∙ Performed cost-cutting modifications that improved safety and boost machine productivity.

∙ Maintain high standards of excellence.

Portfolio

CONTACT Me

If you have any questions or feed back, please contact me here.